| Back to |

The Fine Particulate Agglomerator™

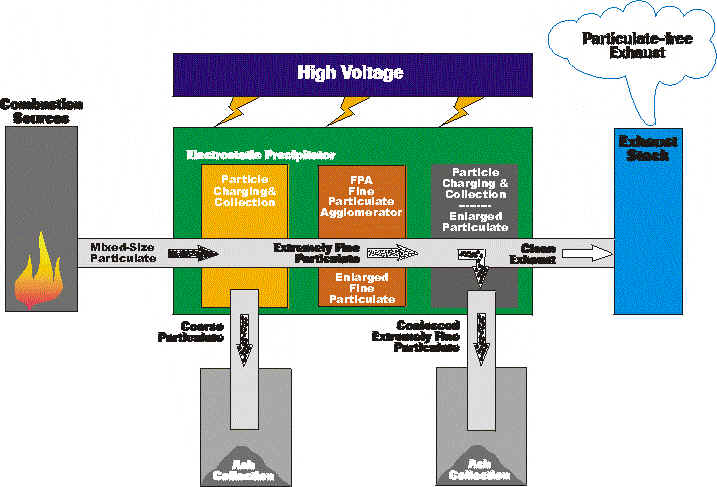

Environmental Elements Corporation’s Fine Particulate Agglomerator™ (FPA) provides a new way to control sub-micron sized particulate emissions from utility and industrial stack discharges. The control of fine particulate emissions is important as they contribute significantly to stack opacity. More importantly, the EPA has identified them as a health risk.

Historically, fine particulate (sub-micron-sized materials) has been very difficult and expensive to control and collect using conventional emission control equipment such as electrostatic precipitators (ESP’s) and fabric filters (FF’s). FPA technology applies the basic principles of ESP science and uses it to promote particulate growth via agglomeration within an ESP rather than attempting to collect it in a conventional manner. This approach makes it possible to change fine particulate into larger, more easily collected and controlled size. This is achieved by using the principles of laminar flow.

It has long been known that collection efficiencies of 100% could be achieved in ESP’s when they are operated in the laminar flow regime. To realize the benefits of this effect, a region of streamline flow conditions and electric field characteristics is created within the confines of a conventional ESP. Ideally, this is done in the second field of an ESP, which is equipped with at least three and preferably four fields.

These conditions promote the interaction of fine particles among themselves and with larger particles. This interaction results in the formation of larger particles. These larger particles, which are easier to collect than fine particulate, can then be collected in the downstream fields of the unit. The schematic diagram depicts the process.

FPA HISTORY AND RECENT APPLICATIONS

The development of the FPA is the result of an exhaustive five-year development effort by EEC. Extensive laboratory tests and modeling programs resulted in a system design that was ready for field demonstrations in pilot-scale projects. Pilot studies have been completed in both conventional utility installations, as well as pulp & paper recovery boiler installations. In 1996, the first commercial industrial power demonstration unit was installed in Lynchburg, Virginia. Then in 1998, the first full-scale utility demonstration unit was installed at Wisconsin Electric’s Presque Isle station.

APPLICATION POTENTIAL

We at EEC view the FPA as an exciting new option to conventional fine particulate control methodologies. It is also an excellent retrofit technology that is effective in enhancing the performance of existing ESP’s. It can usually be installed within the existing equipment envelope with only minor unit modification requirements.

To find out if this technology is compatible with your installation, please contact us at the number shown on the back of this brochure for a free, no obligation evaluation.

EEC BACKGROUND

Environmental Elements Corporation, the Advanced Air Quality Research (AAQR) parent company, is a leading supplier of air pollution control systems serving the power generation and industrial markets. EEC began as a division of Koppers Company over fifty years ago, supplying electrostatic precipitators to the steel, cement, and power industries. In 1983 EEC became an independent private company, and in 1990 it became a publicly held company which is now listed on the New York Stock Exchange under the symbol "EEC."

Since its beginning, EEC has evolved into a company supplying a wide range of high quality air pollution control products such as dry and wet electrostatic precipitators, pulse jet and reverse gas fabric filters, and dry scrubbing technologies such as rotary atomizer spray dryers and circulating fluid beds.

EEC serves all major markets for pollution control from stationary sources. EEC is a major supplier of air pollution control equipment for utility and municipal waste incinerators, and other industrial applications such as the pulp and paper industry. In addition, EEC provides a complete range of aftermarket services.

For further information on the Fine Particulate AgglomeratorTM, please contact:

Mr. Robert W. Tisone

Vice President, Project Operations

Telephone: (410) 368-7104

Fax: (410) 368-7252

Dr. Paul L. Feldman

Vice President, Advanced Air Quality Research

Telephone: (410) 368-7239

Fax: (410) 368-6721

Mr. Paul J. Balasic

Director, Regional Power Industrial Sales

Telephone: (410) 368-7143

Fax: (410) 368-6721

3700 Koppers Street

Baltimore, MD 21227

Telephone: (410) 368-7000

Fax: (410) 368-6896

Back to top

Back to the Environmental Elements Corporation introductory page.

Last updated: May 10, 2009.

Copyright © 1997 TRK Engineering

Services, Inc. All rights reserved.

For more information contact: TRK Engineering Services - 95 Clarks Farm Road - Carlisle,

MA 01741 - Telephone: 978-287-0550 - Fax: 978-287-0569 - email: trkeng@apcnetwork.com