Pictures of Alignment Issues in the ESP

Good collecting plate to discharge electrode alignment is important to optimum ESP operation. Close clearances and jagged or sharp edges will promote premature spark-over which can limit power and ultimately, the efficiency of the precipitator.

The electrode should be centered in the gas passage between the adjacent collecting plates. Allowable tolerances vary with a number of factors however, most manufacturers specify 1/4″ of center for initial installation of wire electrodes in a new ESP. Equally important is the position of the electrode relative to the stiffener baffles on the collecting plates. Electrodes should be centered between stiffener baffles. The stiffener baffles provide a “sharp” edge which can promote sparking when in close proximity to a discharge electrode. Minimum acceptable clearances are usually 1-1 ½ times the acceptable cross gas flow tolerance. Shrouded wire discharge electrodes help to prevent spark-over to the top and bottom collecting plate stiffeners. In the TOP photo the discharge electrodes are not centered properly in the gas passage and need to be centered. The barbed wire electrodes in the photo BELOW are in too close proximity to the collecting plate stiffener baffles and need to be repositioned.

When a high voltage support insulator is replaced, the collecting plate to discharge electrode alignment can be affected and should be checked. Once proper alignment has been established, the retainer angle on the support nut should be reinstalled to prevent movement of the support nut. The nut maintains the relative position of the collecting plates and discharge electrodes

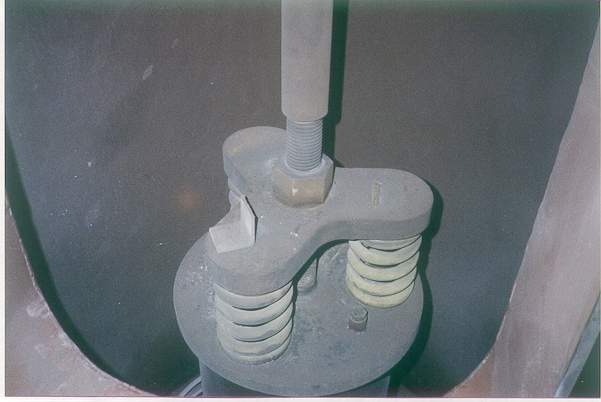

Inspect the position of the wire discharge electrode weights in the lower weight guide frame. There should be no binding of the weight in the guide frame and there should be adequate allowance for thermal growth. Note the position of the weights in the TOP photo. The position of the lower weight guide frame does not allow for any on-line thermal expansion of the wire electrode without the weight bottoming out in the guide frame. This reduces tension on the associated wire electrode and allows it to go slack and whip in the gas stream. The movement of the electrode in the gas stream causes repeated localized spark-over which will adversely affect power levels and will lead to the eventual failure of the wire. The weights in the photo below BOTTOM are positioned properly. Tensioning of hanger wires / cables should also be verified.

Collecting plates that have been damaged due to corrosion, bowing or repeated erosion from spark-over can provide a jagged edge or reduced clearance that promotes premature spark-over. Discharge electrode wires adjacent to damaged sections of collecting plate should be removed, or the collecting plate should be repaired.

LEFT: Kinks in the discharge wire create a close clearance to the plate baffles.

RIGHT: Corrosion of the corona shield on the underside of the support insulator provides a jagged edge which promotes spark-over.

LEFT: Note the erosion of the discharge electrode wire shroud and collecting plate stiffener baffle due to spark-over from reduced clearance.

RIGHT: Bent emitting pins / spikes on rigid discharge electrodes (RDE)

LEFT: The high voltage connection is not centered in the bus duct and does not provide sufficient clearance.

RIGHT: This bus bar is not centered properly in the duct and is promoting spark-over. The white discoloration on the tip of the bar is evidence of corona generation.