Pictures of Air Inleakage in the ESP

Air / water inleakage can have a drastic adverse affect on precipitator operation. When outside air / water is drawn into the precipitator system, gas volume, gas velocities, gas temperature and moisture content of the gas is affected which can modify resistivity and reduce treatment time. Additionally, inleakage promotes corrosion and can cause reentrainment of collected material. Sources of air inleakage are often ignored as insignificant, however, their cumulative affect can be great. Below are examples of typical Sources of inleakage.

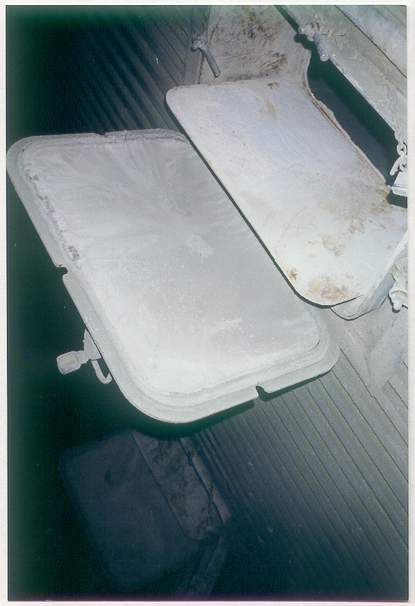

LEFT: The ash patterns on the inside of this hopper door indicate air inleakage. Air inleakage in the hopper area can cause reentrainment of collected material as well as corrosion of overhead collecting plates.

RIGHT: Holes in a side access door coaming allow outside air to penetrate the ESP, causing zones of high velocity and corrosion of internal components.

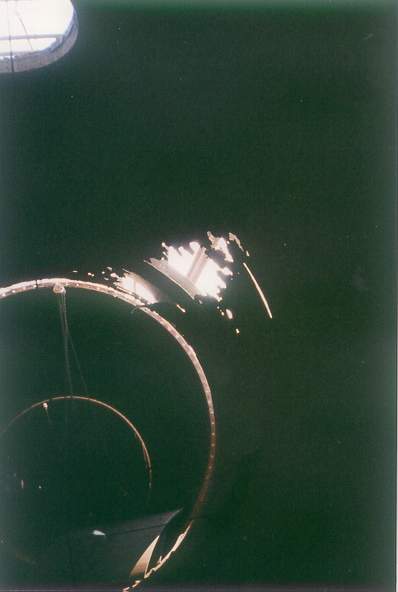

LEFT: The collecting plate shown in this photo is adjacent to a leaking side access door. Air inleakage has destroyed the lower portion of the collecting plate. The resulting jagged edges will promote spark-over and lead to the eventual failure of adjacent electrodes.

RIGHT: Corrosion of inner surface of access door due to air inleakage.

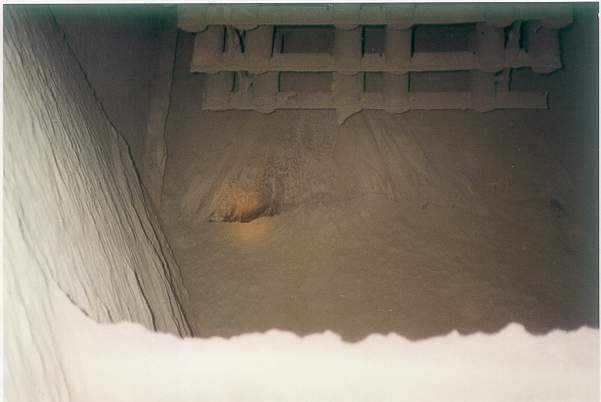

Eliminating air inleakage in the hopper area is crucial to reducing corrosion, and to preventing reentrainment of collected material and hopper plugging. TOP: Note evidence of air inleakage at the hopper flange. BELOW: Material handling systems (screw conveyor) are often sources of air inleakage.

LEFT: Although rotary valve blades allow adjustment to obtain a seal, this valve is worn along the edge and allowing air inleakage.

RIGHT: Both double dump valves are propped open. This may temporarily help material flow, but the resulting air infiltration can cause hopper buildups, corrosion and dust reentrainment.

The open test post in the inlet duct is a source of inleakage.

LEFT: Inspect rapper boot seals and pipe sleeves as sources of inleakage.

RIGHT: The insulation was removed from the precipitator inlet ductwork to expose large corrosion holes over the entire length of duct. These holes allowed for significant inleakage. ESP performance would vary with temperature and weather conditions.

Slide gates can be a source of inleakage. Seals should be inspected and replaced if evidence indicates inleakage

Inspect integrity of expansion joints and repair or replace as necessary to eliminate inleakage.