Pictures of Gas Distribution Problems in the ESP

Good, uniform gas distribution is important to ESP performance. Poor gas distribution can diminish ESP performance by creating high velocity zones which reduce treatment time of the gases, allowing gases to bypass the treatment zone of the ESP, reentraining collected material back into the gas stream, and promoting material buildup. Gas distribution can often be evaluated in the field during a dirty inspection of the ESP by observing buildup patterns, or the lack of them, on the internal components of the ESP and inlet and outlet ductwork. Corrective measures can often be implemented without the need for a model study. Air infiltration is an external factor that can significantly impact gas distribution.

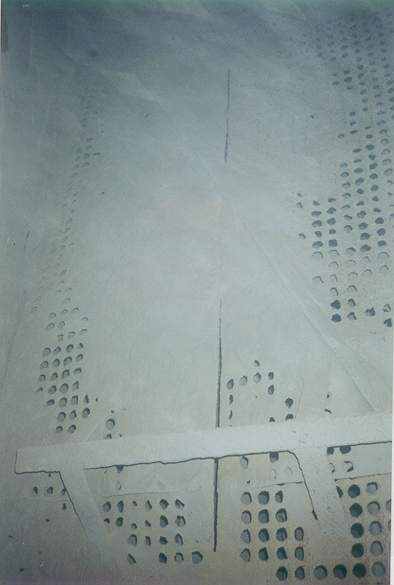

Gas distribution can be evaluated by observing buildup patterns. The buildup on the downstream side of this perforated plate indicates gas flow is expanding downward and to the left. These patterns can be used to devise corrective measures.

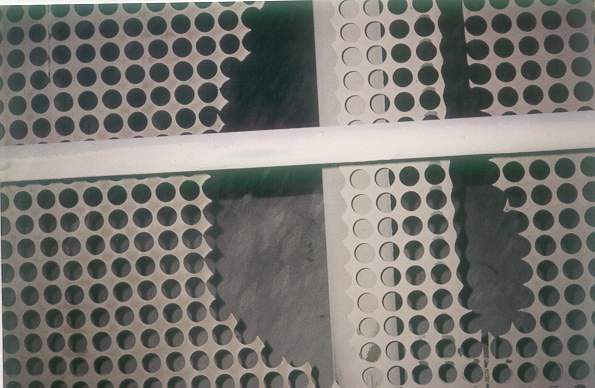

The perforated plate at the inlet flange to the precipitator has been cut along the bottom to promote material flow into the hopper. This has produced a high velocity zone at the bottom of the treatment zone evidenced by scouring of the lower portion of the collecting plates. It also is promoting reentrainment of collected material in the hopper back into the gas stream. BELOW: The installation of a “snowfence” at the bottom of the perforated plate maintains gas distribution while at the same time allowing material to flow into the hoppers.

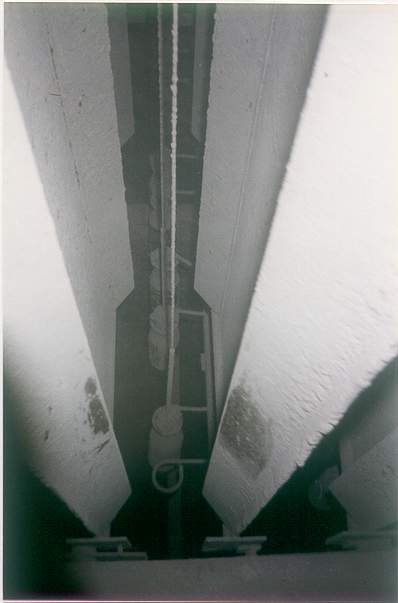

LEFT: Blockage of the inlet turning vanes will create gas distribution problems in the ESP.

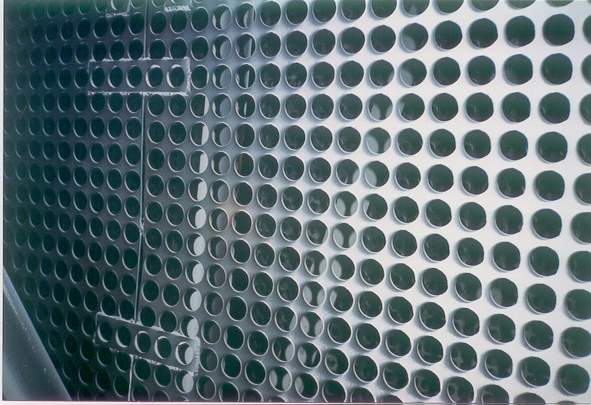

RIGHT: Perforated gas distribution plates help to promote uniform gas distribution. If buildup occurs, for whatever reason, it can cause distribution problems in the ESP, which can lead to performance problems.

The collecting plates, wire electrodes and weights are scoured clean, indicating a very high gas flow and sneakage along the bottom of the ESP.

A void created by improperly installed turning vanes, located upstream of the pipe supports and perforated plates, can be seem by the heavy material deposits on the vertical support pipes. This type of buildup indicates little or no flow. One would expect the pipe to be bare metal clean from this angle. A close look at the perforated plate also shows a reverse flow pattern back through the plate. Because the gas is trying to fill this void.

Channeling of gases down the middle of an inlet nozzle has caused erosion of the perforated gas distribution plate. This will produce a high velocity zone in the precipitator.

The polished sections of the wire electrode shrouds indicate gas flow above the treatment zone.

LEFT: Polishing of the collecting plates in the first field indicates high gas flow along the bottom of the precipitator. This can cause reentrainment of the dust and allow gas to bypass the treatment zone by sneaking under the field. It can also cause the wire electrodes to swing, reducing the spark-over voltage and fatiguing the wires.

RIGHT: This pattern was evident all the way through the ESP. The collecting plates were polished in the fourth (outlet) field.

Buildup patterns on the wire shrouds and weights indicate significant gas flow beneath the collecting plates.